Briquette – Light Weight Building Material

Briquette is a light weight building material. It consists of volcanic silicate sourced, amorphous and glassy pumice or pumice stone, and cement. This is obtained by molding and pouring the mortar. Concrete briquette walls are found on the walls of skeletal structures, non-load-bearing or at most two-storey masonry structures.

Concrete briquettes contain filling materials such as sand, gravel, tuff slag, sifted boiler slag, brick and tile fragments, pumice (pumice stone). These materials mix with cement and water in a moist consistency. They are formed by forging, pressing, or vibrating in special molds.

Briquette walls made of sand and gravel are heavier than others. On the other hand, they are more resistant to load and weather conditions. The borders with pumice are mostly preferred because they are more successful in lightness and sound, and heat insulation.

The unit volume weight of the concrete to be produced with the product should not be more than 1600 kg/m³. They are more economical than other wall elements. Plug-in products eliminate the need for mortar. Therefore, it provides advantages in terms of time, labor and cost. In addition, having a high degree of thermal insulation properties reduces fuel consumption compared to bricks. Sound insulation properties are 50% higher than brick blocks. Since it does not contain any material other than cement, pumice, and water in its structure, it does not pose a danger to human health. The walls provide the moisture balance of the environment due to their porous structure and allow the building to breathe.

Weight of Briquette

Single-row -800 kg/m³

Single-row -800 kg/m³

Two-row -9000 kg/m³

Three-row – 1000 kg/m³

Hollow block- 700-900 kg/m³

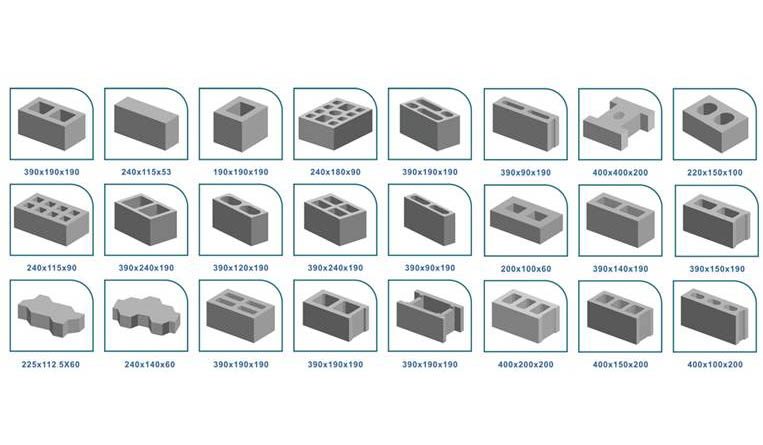

Briquette Dimensions

Manufacturers either solid or hollow, with mortar slots on the sides. Its dimensions are usually 6 x 11 x 23, 10 x 20 x 40, 20 x 20 x 40 and 20 x 30 x 40 cm. The tolerance in dimensions should not be more than +-3mm in all dimensions and also +-2mm in tapers or slopes.

The wall thickness between the holes and the edges should not be less than 3 cm in perforated briquettes, which generally made with two holes, and five sides are closed, and one side is open. In addition, the total of the hole volumes should not exceed 50% of the book.

Advantages of Briquette

- Briquette is the cheapest among light insulation materials.

- Its very low thermal conductivity coefficient provides high thermal insulation.

- In buildings, window sizes can enlarged, and wall thicknesses can reduced.

- Porous internal structure provides sound insulation and sound absorption.

- It is much lighter than materials with the same volume and properties produced with normal aggregates.

- Its smooth surface saves labor and plaster.

- Compressive strength is high (25 – 70 MPa).

- Freeze-thaw resistance is high.

Thermal Insulation Properties of Briquettes

Briquette elements have excellent thermal insulation properties due to their low unit weight and porous structure. The fact that the pumice aggregates in its structure contain many homogeneously distributed tiny pores considerably reduces the thermal conductivity coefficient. As a result, fuel consumption decreases, window widths in buildings can increased, and wall thicknesses can thinned.

Sound Insulation Properties of Briquettes

Briquettes have good sound insulation properties thanks to the homogeneous cavities they contain, their low unit weights, and the absence of crystalline pore water. These features also cause sound waves to dampen the surfaces of the elements produced with the product. Thus, it provides good sound insulation and acoustics.

Moisture and Vapor Permeability

Briquette plays an essential role in maintaining the moisture balance of the environment due to the pumice aggregates. When the ambient humidity rises, it traps some of this moisture in its structure and balances the environment. In the same way, the decrease of ambient humidity gives excess water to the environment. The pore structure of the product contains independent spaces from each other, and the pores it has are insulated with a membrane, so it does not hold water and water vapor.

Fire Resistance

In the briquette production processes, no organic material used in the structure. It also known that the pumice aggregates used in the production do not contain organic matter. For this reason, it operated as wall elements during any fire that do not burn, do not cause glare, and do not create smoke.