All About Nonwoven Fabrics

What is Nonwoven Fabric?

How is Nonwoven Fabric?

Does Nonwoven Fabric Make You Sweat?

Nonwoven Fabric’s Features

Nonwoven Fabric’s Usage Areas

Is Nonwoven Fabric Flexible?

Does Nonwoven Fabric Shrink When Washed?

Does Nonwoven Fabric Keep You Warm?

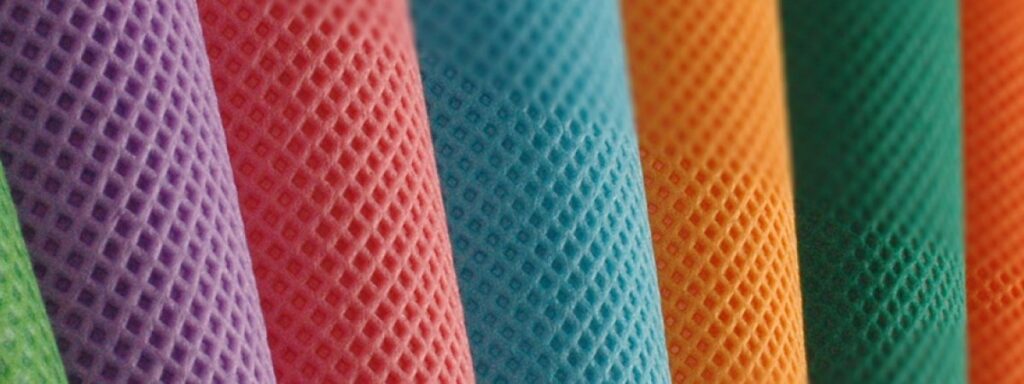

Nonwoven fabrics, which are preferred in all kinds of bags and textile products due to their unique features, are among the fabric types with extremely low production costs. All about Nonwoven fabrics will be explained below.

Nonwoven fabric is a type of fabric with antibacterial properties manufactured for private use.

What is Nonwoven Fabric?

Without weaving or knitting of fibers of different lengths, people produce it by combining mechanical, chemical and heat. Although its strength is weak next to classical fabrics, people use it in the field of textiles due to its affordable cost.

Without weaving or knitting of fibers of different lengths, people produce it by combining mechanical, chemical and heat. Although its strength is weak next to classical fabrics, people use it in the field of textiles due to its affordable cost.

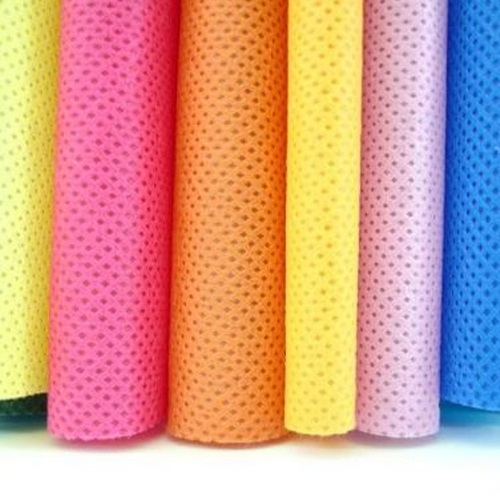

How is Nonwoven Fabric?

Pople obtain it by the application of chemical, heat and mechanical methods that enable the fibers to stay together after the stage of cheesecloth or layering. Also, people obtain it by felting or bonding methods. Furthermore, people use nonwoven fabrics in disposable products.

Does Nonwoven Fabric Make You Sweat?

Nonwoven fabrics do not sweat as they breathe. Since it is a natural and thin fabric, it prevents sweating by allowing the body to breathe.

Features

It is breathable, lint-free, heat-resistant, light, soft, hard, stable, tear-resistant, water-repellent, draping and absorbent. Non-woven fabrics are not very durable. People produce it in different weights. People produce nonwoven fabrics in molded shapes which do not wear out and are easily piled. Since people produce it from recycled fibers, it can be made soluble. People can soften them by heat. Since it is hard and stable, it retains its shape for a long time and prevents the formation of wrinkles in the fabric up to a certain level. Due to its antibacterial properties, it is considered a natural product and prevents the formation of allergic or microbial substances on the fabric.

Usage Areas

Nonwoven fabric has a wide range of uses because people produce it with high machine efficiency, high worker speed and low cost. Moreover, people use it in the fields of textile, geotextile, medical, hygiene, furniture and shoes. Also, people use them as an internal reinforcer or interface in textile products. It is a product that is used in many different fields such as agriculture sector, automotive industry, medicine – space and defense industry. The fact that the production cost is very low and people produce it in a short time and requires less workers has paved the way for the use of nonwoven fabric in every field that comes to mind.

Also, people use them as a composite to make heat and cold resistant clothing such as diving suits, sandbags, bulletproof vests. In the field of textiles such as industrial fabric carpet backing, auto upholstery fabric and sailing fabric, people use it as geotextile in greenhouse cover and drainage construction. People also use it in medical textiles such as tape, artificial vein and dialysis. Furthermore, people use it in the construction of industrial protection nets such as fish, camouflage and protective nets.

Is Nonwoven Fabric Flexible?

Nonwoven fabric has a very rigid structure that protects the shape. Therefore, it is not among the flexible fabrics.

Does Nonwoven Fabric Shrink When Washed?

Nonwoven fabrics are hard and stable fabrics. However, it can deform at high temperatures and when wet. It is possible for the nonwoven fabric to dissolve at high temperature. Also, nonwoven fabric may become weaker when wet.

Does Nonwoven Fabric Keep You Warm?

Nonwoven fabric is a type of fabric that is thin and has low strength. For this reason, people use in many textile products to create an interface or to serve as an internal reinforcement. Therefore, it does not have the feature of keeping people warm alone.