Building a Boat : Different Stages

The construction of a floating structure for building a boat (motorboat, restaurant, barge, pontoon, …) requires about 18 months from the initial request of the client to design his project to the final delivery. Different teams are involved throughout the process, which can be divided into 7 stages:

1. Design

2. Industrialization study

3. Arrival of raw materials

4. Manufacturing of the hull

4.1. Prefabrication of blocks or panels in the workshop

4.2. Mounting/welding on the assembly marble

5. Armament and layout

6. Launching and finishing

6.1. Preparation for the launch

6.2. Floating finish

Discover below these detailed steps and how our different professions, embodied by passionate professionals, guarantee the success of each of them for building a boat.

1. Design for building a boat

Just like the construction of a building or a dwelling, shipbuilding is subject to a preliminary design study called “Preliminary Summary Design (PSD)”. For building a boat, overall, design and structural plans allow to define all the technical and physical characteristics of the future boat. These elements are defined with the client, an architectural firm and an assistant project manager who rely on the standards and rules imposed by the future location, the final use of the structure as well as the various environmental and safety standards associated with it. From these elements, the “studies and projects” team can establish its first commercial proposal.

2. Industrialization study for building a boat

During this stage, the architects ‘ plans are transformed into a manufacturing plan adapted to the method and the infrastructures (means of production, handling and structures.). To start building a boat the sample of the structure is checked. Further more the team details the work plan by plan, element by element, from the panels used to create the bottom, the partitions to the different profiles, flanges and other elements to stiffen the structure, passing by the different elements constituting the work. The project managers in collaboration with the supply manager carry out the various orders relying on the supplier partners.

3. Arrival of raw materials

In building a boat, we receive on the site the raw materials and the various oxy-cut parts resulting from the nomenclature and cuttings established in the previous phase. The warehouseman processes this. Then, it is unloaded with a crane by the production teams. The crane operator is guided from the ground by radio by one of the boilermaker team leaders and his team in charge of securing the load during handling with different lifting accessories (e.g. spreaders, sheet metal tongs…). One of the car operators handles other elements.

4. Manufacturing of the hull

4.1. Prefabrication of blocks or panels in the workshop

In building a boat, crane, trailer and forklift truck transport the various elements necessary for the construction of the hull (sheets, profiles…) to the boiler workshop according to the process needs. In the workshop, the boilermakers bend and preform the elements of the future work with the help of various machine tools according to the desired shapes. Then they pre-assemble these boiler-made or mechanically welded elements to prepare them for the assembly phase and then for welding by the welders.

4.2. Mounting/welding on the assembly marble

During the assembly by the boilermakers, at each panel assembled to constitute the various compartments of the boat, we align the blocks with the telescope by taking as reference the assembly plate levelled at the beginning of the construction. In building a boat, the charged team places the panels on the marble with a crane and brings together with the help of jacks and hoists until they have placed the elements. At the end of the assembly, the welders weld all the elements together. At the end of this phase, the outer hull and the different compartments of the boat are assembled.

5. Armament and layout

Once we have mounted the hull and the various decks, various trades intervene to dress the hull of the boat, painters, masons, electricians, insulators, pipefitters, mechanics of edges and workshops… Each of these trades has its own requirements for carrying out its activities. The boilermakers and pipefitters thus make reservations at the places defined in advance on the recollage plans.

Then, the electricians and edge mechanics begin to lay the equipment they are in charge of. Of course, these various activities create risks related to the intervention of these different trades in spaces as small as the hull of a boat. For this reason, the project manager and the production manager ensures the proper realization of these works in complete safety in consultation with the safety and environment facilitator.

6. Launching and finishing on building a boat

6.1. Preparation for the launch (ripping/shifting/painting of live works)

After that, the shore draw team prepares the launch operation. Firstly, we shif the structure which consists in shifting the boat from the marble to the draw carriages on land, allowing the launch. This operation is carried out by means of so-called hauling or shifting winches which make it possible to translate the structure of the assembly marble as far as the axis of the draw track on land. Therefore, this translation allows the welders to finalize the bottom welds and painters, permanent subcontractors of the site, to paint the vivid works (part of the structure to immerse).

6.2. Floating finish

Finally, for building a boat, during this stage, crane places indicator lights on the trolleys on the ground. They allow to materialize the submerged trolleys and thus maintain the boat perfectly positioned on these trolleys in the axis of the track. The shore team can then progressively lower the structure on the rails until it reaches the water. After that, our team put the boat in the dock for finishing touches and navigation tests. Lastly, in the presence of the client, we carry out these tests. The project manager in charge of the work is also present with an on-board mechanic and an electrician to take over the motorization and turning part of the work if necessary.

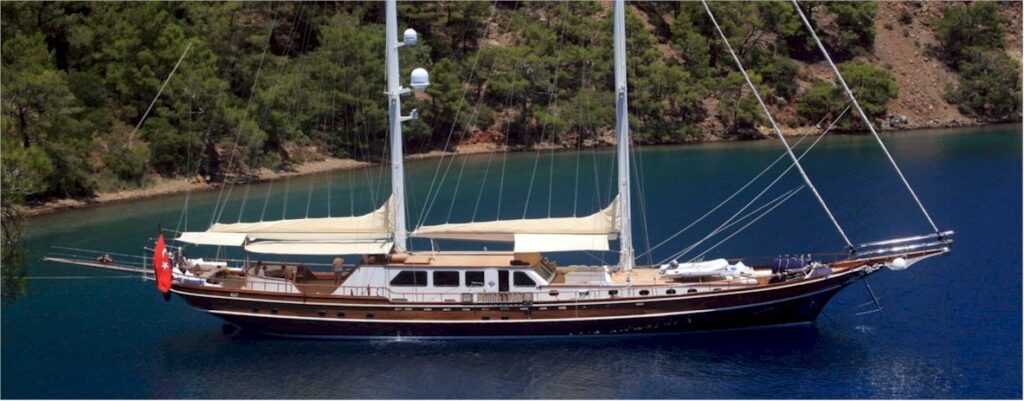

If you want to know more about boatbuilders in Turkey, please visit our Turkish marine sector yachting listings here or here.